What Is an Ohio Special Boiler? A Complete Guide to Ohio’s 360 sq. ft. Rule

Dec 05, 2025

What is an Ohio Special Boiler?

Ohio Special Boiler Definition: An Ohio Special Boiler is a steam boiler intentionally designed with a heating surface just less than 360 square feet, keeping it below the operator-licensing threshold for continuous manned attendance defined in Ohio Revised Code (ORC) 4104.05. “Ohio Special” is an industry term for this design strategy and does not appear in Ohio law.

Section 4104.05 of the ORC says

"(A)...no person shall operate a low pressure steam boiler that has more than three hundred sixty square feet of heating surface, unless one of the following applies to that person:

(1) The person is licensed as a steam engineer, high pressure boiler operator, or low pressure boiler operator...

(2) The person is working under the direct supervision of a steam engineer, high pressure boiler operator, or low pressure boiler operator.

(B)...no person shall operate a power boiler that has more than three hundred sixty square feet of heating surface, unless one of the following applies to that person:

(1) The person is licensed as a steam engineer or high pressure boiler operator...

(2) The person is working under the direct supervision of a steam engineer or high pressure boiler operator.

(C)...no person shall operate a stationary steam engine at more than thirty horsepower unless one of the following applies to that person:

(1) The person is licensed as a steam engineer...

(2) The person is working under the direct supervision of a steam engineer."

Source (Ohio Revised Code Section 4104.05, Effective January 30. 2014)

Because of this threshold, manufacturers created a specific class of boilers that deliver more steam output while legally remaining under the heating-surface limit. To avoid this requirement, boiler manufacturers will build a boiler with an oversized burner to increase steam capacity, while keeping the heating surface just below 360 square feet. Typically, the boiler will have 358- 359 square feet of heating surface. This design workaround is unique to Ohio. Since boiler laws vary by state, the term “Ohio Special” has become industry shorthand for this legal engineering exception.

Type of Boiler Limited by the 360 SQ. FT. Rule

The 360-square-foot heating surface limit applies only to steam boilers. It does not apply to:

- Heating hot water boilers

- High-pressure, high-temperature water boilers operating at a pressure greater than 160 PSIG (11.03 bar) and/or temperature greater than 250°F (121.1°C).

- Thermal fluid heaters

- Potable water heaters

Licensing Requirements by Boiler Type

All steam boilers, firetube, watertube, or cast iron sectional, with heating surfaces greater than or equal to 360 square feet, require a licensed operator under the ORC. However, in practice, Ohio’s Division of Industrial Compliance (DIC) does not enforce this requirement for steam cast iron sectional boilers, despite the ORC containing no explicit exemption.

If you are installing a steam cast iron sectional boiler with over 360 square feet of heating surface, it is highly recommended that you obtain written confirmation from the Ohio Chief Boiler Inspector stating that a licensed operator is not required for your installation.

Why are Ohio Special Boilers Typically only Firetube Boilers?

To reach useful steam output while staying under 360 square feet of heating surface, the vessel must be overfired. Firetube geometry allows burner heat to pass through a limited number of tubes, keeping the surface area low. Watertube designs inherently use a large heating surface to safely absorb combustion heat with using all of the tubes. You may be able to find a manufacturer who makes an Ohio Special watertube boiler, but they are not popular and are limited in capacity versus firetube boiler designs.

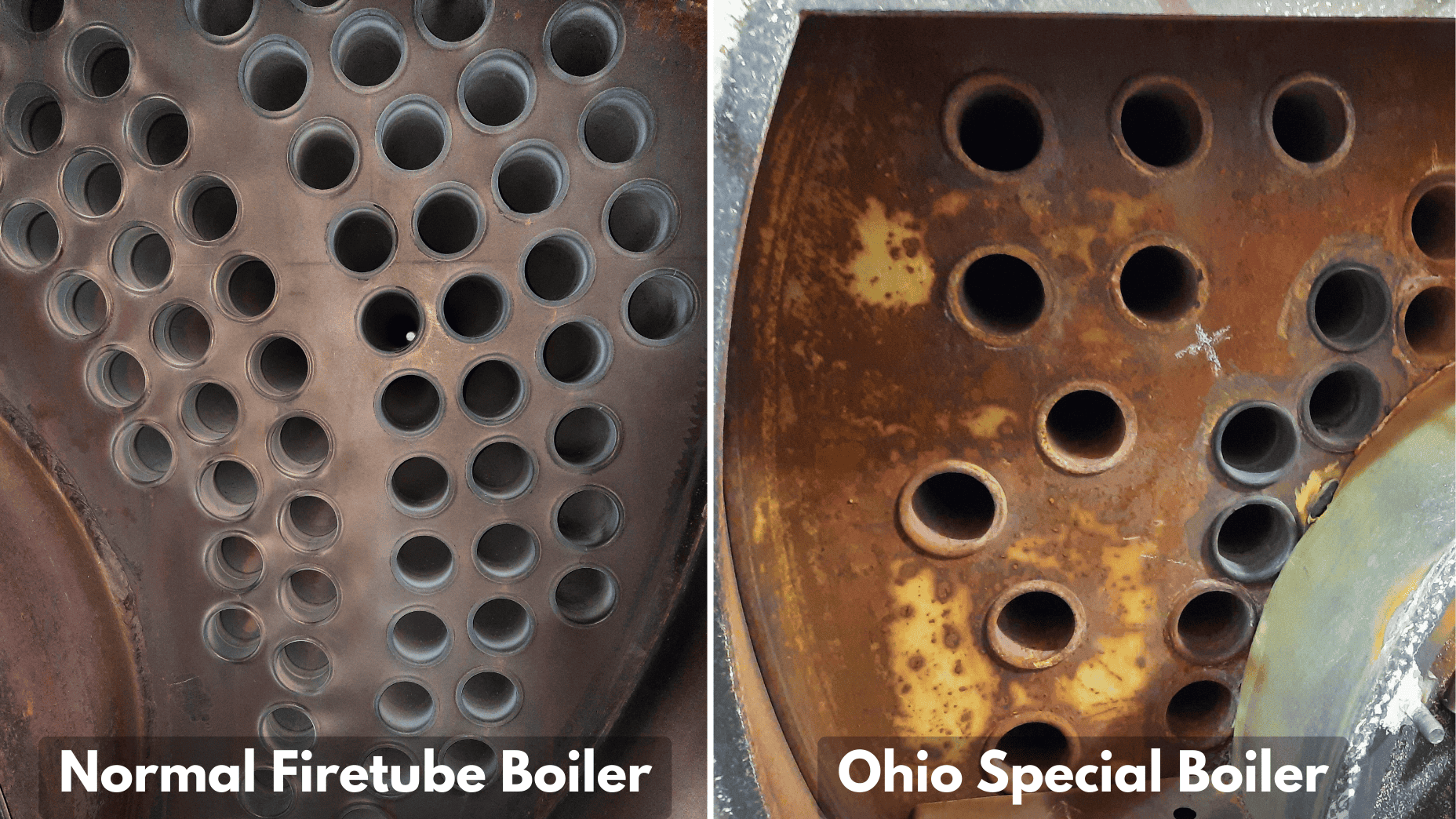

Comparison between the number of tubes on a typical firetube boiler vs an Ohio Special firetube boiler. Notice how spaced out the tubes are on the Ohio Special.

Boiler Room Design Considerations

When designing a new boiler room or retrofitting an existing one, engineers and contractors need to understand the benefits and downsides of selecting a boiler above or below the heating surface limit.

When selecting a boiler with 360 square feet of heating surface or less, direct supervision by a licensed person is not required. The benefit is that the boiler owner does not have to find and hire licensed boiler operators to supervise the boilers while they are operating. If the boiler plant runs 24/7, licensed operators must be on-site, which means people must work nights and weekends. If the facility is short-staffed or people call out sick and there is a gap where no operator is available, the boilers are not legally allowed to operate and would have to be shut down. This would be a very inconvenient and expensive decision in a manufacturing facility, as the product could not be made, putting the facility behind schedule and sending other people home who were supposed to be working on it.

Cost Comparison (Ohio Special vs Normal design)

Choosing Ohio Specials is primarily a staffing and operating-cost decision, not a technical one. If boilers with 360 square feet or less of heating surface are selected, they do not require direct supervision from a licensed operator. This allows the boiler owner to run the boiler plant 24/7 without licensed supervision, reducing operating costs as full-shift coverage is no longer required. If a licensed boiler operator makes $45 an hour and there are three shifts per day, the annual savings would be a minimum ($45 x 24hr x 365) = $394,200 in just payroll costs. The savings would be higher when supervisors, management, materials, scheduling, taxes, and benefits are added to the cost of operating a boiler plant with licensed operators. Not having to worry about finding and managing licensed operators would be the biggest benefit. There are becoming fewer and fewer licensed operators every year as many are older and retiring. There is not the same number of new, younger people to replace them.

In terms of maintenance, the more boilers there are, the more parts and labor are required to maintain them. This increase in the cost of parts and the added labor to service more boilers, compared to fewer larger boilers. However, the savings from the reduced payroll costs of not having to staff licensed operators will offset these added costs. The costs will vary significantly depending on how the boilers are used and the load requirements. It is worth exploring different equipment options based on end users' needs and priorities.

Boiler Design Comparison

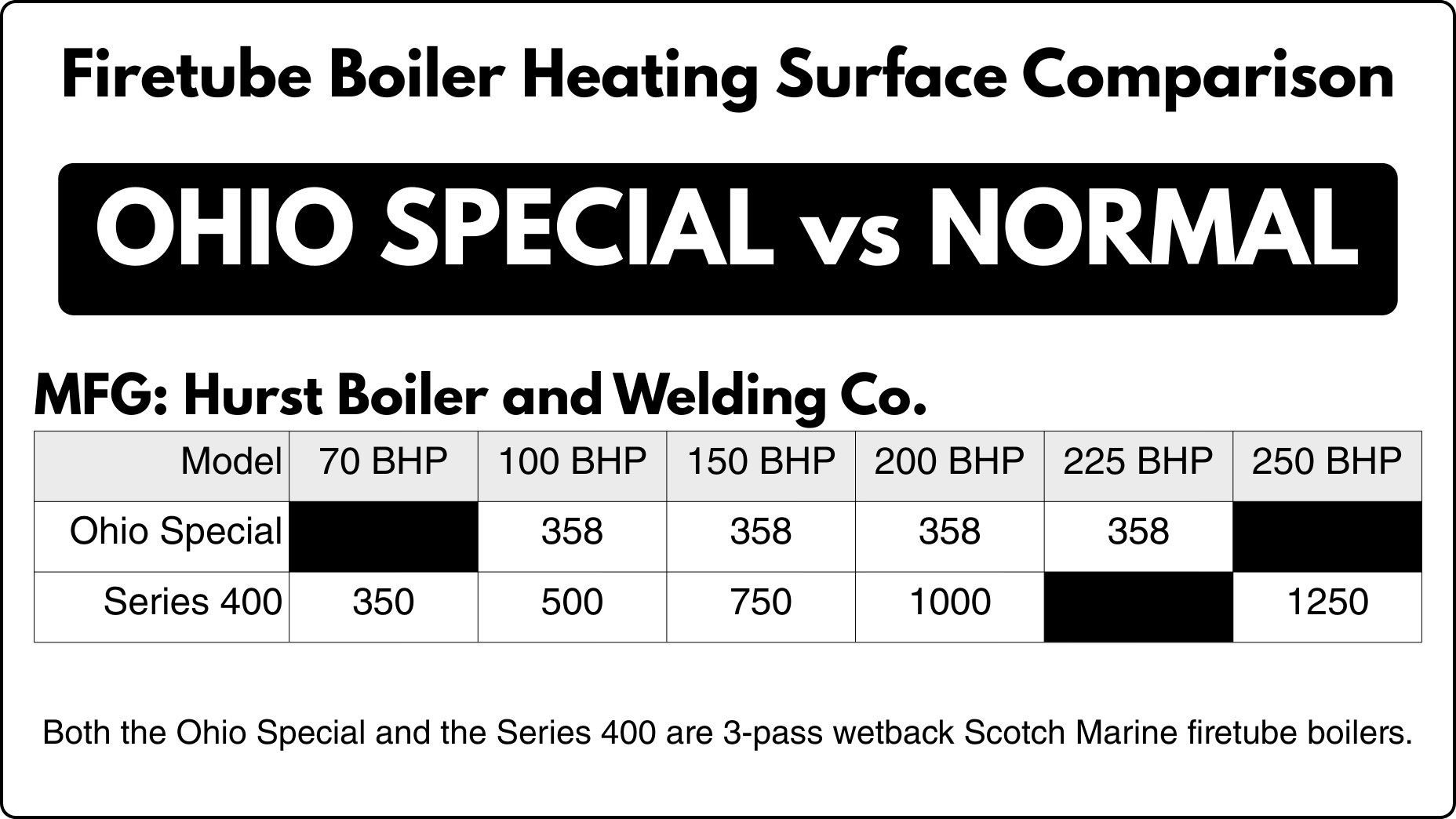

Below is a chart comparing a standard Scotch Marine firetube boiler to an Ohio Special Scotch Marine firetube boiler. Hurst Boiler and Welding Co. designs were used in the comparison, but you would find similar heating surface numbers from other manufacturers. Both boiler designs are 3-pass wetback Scotch Marine firetube boilers. If you look at the chart, you will see the Series 400 model boiler, which is the standard design, has 350 square feet of heating surface at 70 boiler horsepower. Then, at 100 boiler horsepower, the number jumps to 500 square feet of heating surface, whereas the Ohio Special design is 358 square feet. As the boiler horsepower increases, the Ohio Special heating surface area remains the same to stay under the 360-square-foot limit. So if you were to order a 200 boiler horsepower Series 400 boiler and install it in Ohio, because the heating surface is 1000 square feet, which exceeds the 360-square-foot limit, a licensed boiler operator would be required to operate the boiler.

Benefits and Drawbacks of Ohio Special Boilers

The following is a list of the benefits and drawbacks of an Ohio Special boiler. This is a general list and does not apply to every situation. When designing a new boiler room or upgrading an existing one, it is worth exploring different equipment options to determine what is best for the end user. Ohio Specials are not a performance upgrade; they exist to meet a legal threshold at the lowest possible heating surface. This design compromises efficiency and long-term reliability in exchange for reduced operator staffing costs.

Benefits

- The boiler can be installed and operated without a licensed operator in the state of Ohio.

- The boiler owner is not required to maintain a staff of licensed boiler operators to run the boilers.

- The annual boiler operating cost is reduced because a licensed operator is no longer required to supervise the boiler.

- The boiler owner doesn't have to search for a licensed boiler operator to hire, as it can be hard to find one, especially in areas with smaller populations in the state.

Drawbacks

- Lower boiler efficiency due to the reduced heating surface.

- Higher stack temperatures than an equivalent standard design firetube boiler.

- Not all burners can fire into an Ohio Special boiler and run correctly without rumbling.

- Depending on the burner and boiler design, the boiler may not make rate in some higher boiler horsepower designs.

- Cracked tube ends, especially on the first pass. To reduce tube leaks, it is recommended to weld the first-pass tubes.

- More likely to develop cracks in the boiler tube sheet due to the vessel being overfired.

- More equipment to maintain. If (3) 200 BHP Ohio Special boilers are installed instead of (1) 600 BHP standard firetube boiler, the boiler plant has 66% more gaskets, controls, safeties, burners, and parts required to keep the boilers operating correctly.

- Increase in floor space required for multiple Ohio Special boilers instead of 1-2 larger boilers.

- Higher initial cost due to more floor space and equipment required when installing multiple Ohio Special boilers.

Examples of Ohio Special Boilers

Here are some examples of manufacturers that make Ohio Special boilers.

- Burnham Commercial Boilers- Series 3 Ohio Special, Capacities from 100 to 225 BHP. (Source: Burnham Commercial Ohio Special Boiler).

- Cleaver Brooks: CBOS and CEWOS Boilers- Capacities from 100 to 225 BHP. (Source: Cleaver Brooks Ohio Special Boiler).

- Note: A Super Ohio Special Boiler with capacities of 260 BHP or 300 BHP are available by special request.

- Hurst Boiler and Welding Co.: Series Ohio Special, Capacities from 100 to 225 BHP. (Source: Hurst Boiler Series Ohio Special)

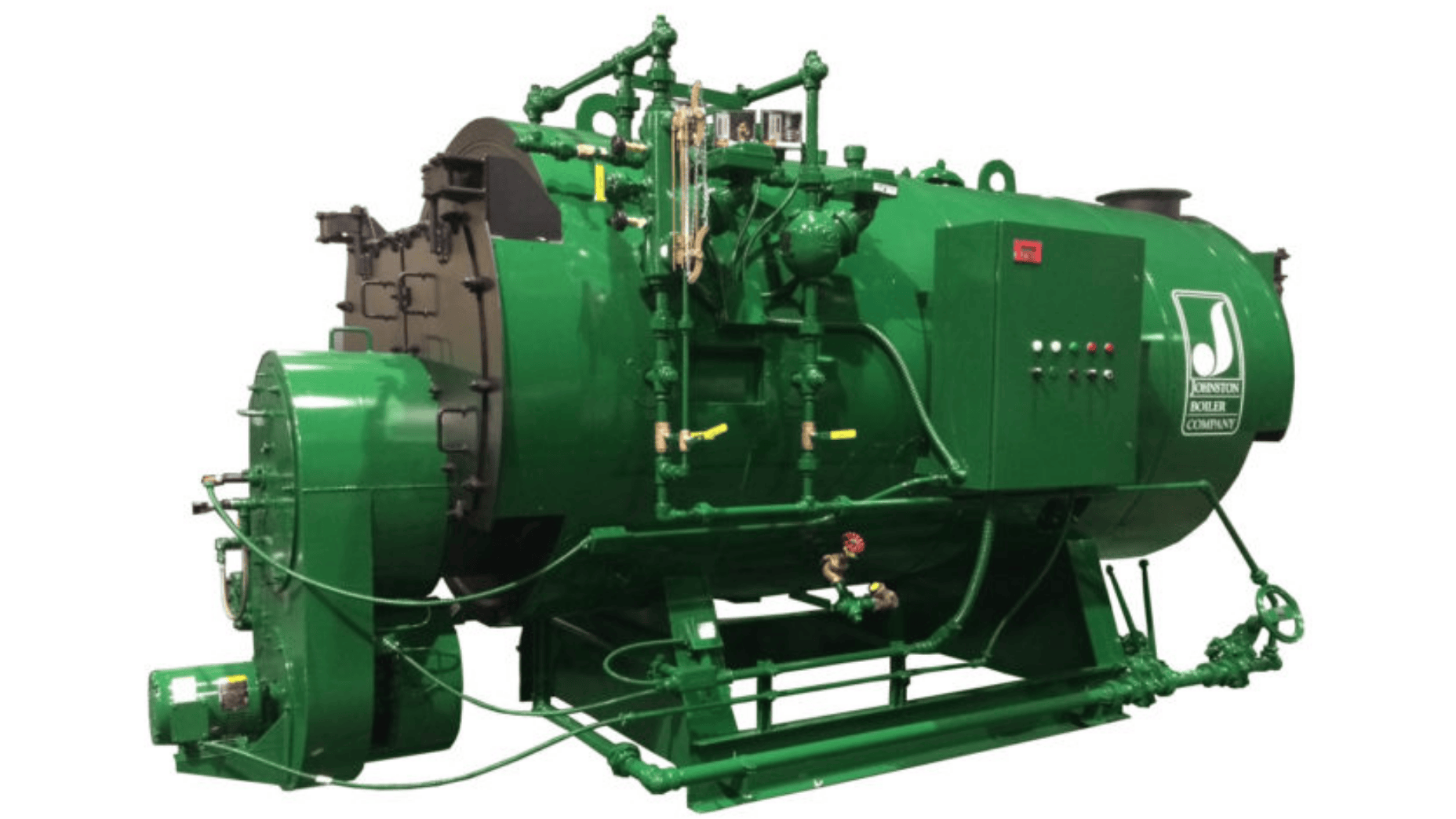

- Johnston Boiler Company: 358 Series Boiler- Ohio Special, Capacities from 80 to 250 BHP. (Source: Johnston 358 Series Boiler- Ohio Special)

- Sellers Manufacturing Co.: Ohio Special Boiler, Capacities from 80 to 250 BHP (Source: Sellers Manufacturing Co. Ohio Special Boiler)

- Note: Since the Sellers Manufacturing Co. boiler is a unique 1-pass design, it is the only Ohio Special firetube boiler in which the pressure vessel is not overfired.

- Superior Boiler: Ohio Special Dryback- Capacities from 80 to 225 BHP. (Source: Superior Boiler Ohio Special Dryback)

- Superior Boiler: Ohio Special Wetback- Capacities from 80 to 200 BHP. (Source: Superior Boiler Ohio Special Wetback)

Johnston Boiler Company 358 Series Ohio Special Boiler

Johnston Boiler Company 358 Series Ohio Special Boiler

Coil Type Steam Generators

An alternative to multiple Ohio Special boilers is a coil-type steam generator, which provides more boiler plant capacity without requiring a licensed boiler operator. These generators are manufactured by popular brands such as Vapor Power International and Clayton Industries. A coil-type steam generator does not have a traditional water level like a Scotch Marine firetube boiler. Water is either recirculated or passes through the heated coils once, depending on the unit's design. The heated water then leaves the coils and enters an expansion chamber, where it flashes into steam. If an isolation valve and relief valves are added between the hot water coils and the steam drum, the steam generator becomes a hot water generator with a remote steam drum. It is no longer a steam generator and therefore is not subject to the 360-square-foot heating surface requirements for a licensed operator.

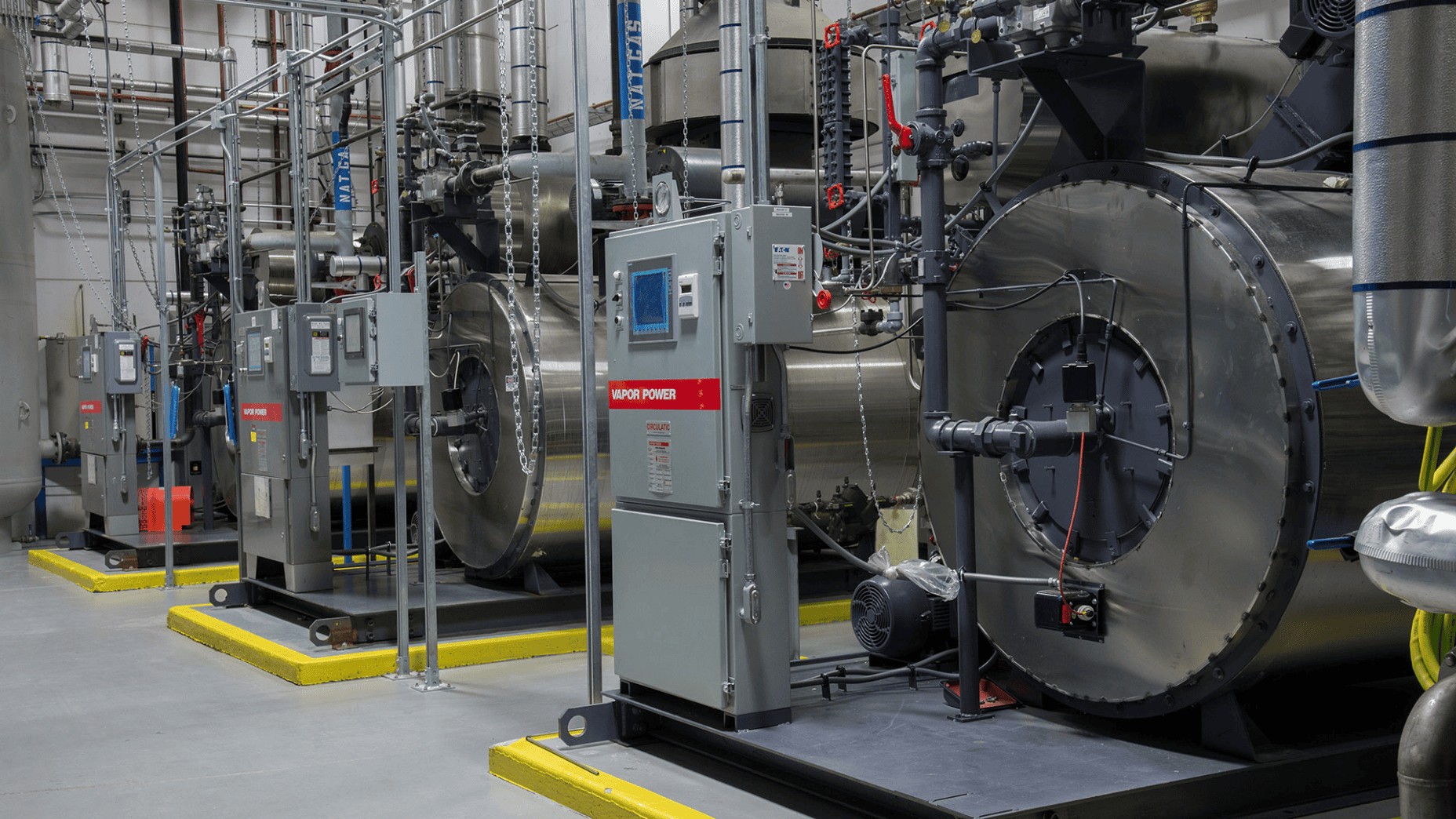

(3) Vapor Power International Circulatic Steam Generators

Coil-type steam generators offer many benefits, including a higher maximum design steam pressure than firetube boilers, rapid warm-up and quick steam production from a cold start in 5 minutes, and rapid response to load swings. They can be a good selection for processes where the load changes rapidly, such as corrugators and injection molding. Operation and maintenance are a little different for a coil-type steam generator vs a firetube boiler, so there will be a training curve if the boiler owner is used to "normal" firetube and watertube boilers. The Ohio Special version of the coil-type steam generator differs from the standard design, so make sure to specify and order the correct design if you select a coil-type steam generator for your boiler plant in Ohio.

Examples of Coil Type Steam Generators

- Clayton Industries: SigmaFire- Capacities from 25 to 200 BHP (Source: Clayton Industries SigmaFire)

- Vapor Power International: Circulatic- Capacities from 75 to 600 BHP (Source: Vapor Power International Circulatic)

- Vapor Power International: Modulatic- Capacities from 18 to 220 BHP (Source: Vapor Power International Modulatic)

Ohio Licensed Operator Exemption

Ohio has the Ohio Administrative Code (OAC). These are regulations and procedures written the state agencies to enforce the Ohio Revised Code (ORC). The ORC is law, and the OAC lays out how that law is implemented, monitored, and where exceptions or alternative procedures are allowed. The Ohio Board of Building Standards adopted rule changes effective January 1, 2015, that established Rule 4101:4-10-01, Licensure and attendance requirements of operators. This rule allows a boiler owner to operate a non-solid-fuel-fired steam boiler with a heating surface greater than 360 square feet without the required continuous manned attendance by a licensed operator.

The additional requirements vary depending on the boiler's fuel input rating.

- Fuel input rating less than 12,500,000 BTU/hr: Automatic controls meeting the requirements of CSD-1.

- Fuel input rating greater than 12,500,000 BTU/hr: Meeting the requirements of NFPA 85 and automatic controls meeting the requirements of CSD-1.

Essentially, more work and paperwork are required to prove to the state of Ohio that the boiler owner is operating the boiler safely. The Ohio Division of Industrial Compliance must approve the boiler owner's exemption from the continuous manned attendance by a licensed operator requirement under ORC 4104.05. This OAC Rule may be worth pursuing if your facility's operational needs align with the benefits of not requiring continuous manned attendance by a licensed operator.

If you want to learn more about the Ohio licensed operator exemption, including the details and process, we have written a separate article here: Ohio Licensed Operator Exemption Explained.

Common Misconceptions

Below are some of the most common misunderstandings we hear in the field regarding Ohio Special boilers and licensing requirements.

Myth: Ohio Special boilers with automatic controls do not need supervision or maintenance.

Fact: Boilers under 360 square feet do not need direct supervision from a licensed operator, but they still require daily check-ins, low-water safety testing, proper water treatment, adding salt to the softener, and bottom blowdowns. The manufacturer’s manual lists daily, weekly, monthly, semi-annual, and annual tasks that must still be followed.

Myth: (3) 100 BHP Ohio Special boilers installed in battery still requires a licensed operator because the heating surface areas of all the boilers add up to over 360 square feet.

Fact: The 360-square-foot rule applies to each boiler individually. A boiler room could have (10) Ohio Specials and still not require a licensed operator, as long as each boiler remains at or below 360 square feet of heating surface.

Myth: Ohio Special is an ASME design category for boiler construction.

Fact: Ohio Special is just a nickname manufacturers use for firetube boilers built intentionally with heating surface just below 360 square feet. They are still built and stamped to the ASME BPVC Code the same way as any other firetube boiler.

Myth: Ohio Special boilers are the only type of boiler allowed in Ohio.

Fact: Any boiler can be installed in Ohio as long as it meets state code. Ohio Special refers only to a boiler with a heating surface area below 360 square feet, so it can operate without a licensed operator.

Myth: Boiler horsepower is what decides whether a licensed operator is required.

Fact: Operator requirements are based only on heating surface area for steam boilers. Boiler horsepower is not the legal trigger. For stationary steam engines, horsepower does matter as the limit is 30 HP without a licensed operator.

Myth: Any boiler with more than 360 square feet of heating surface needs a licensed operator.

Fact: The 360-square-foot limit applies only to steam boilers.

Myth: A steam cast iron sectional boiler is exempt from the 360 square foot of heating surface requirement for a licensed operator.

Fact: No specific language in the Ohio Revised Code exempts steam cast iron sectional boilers from the heating surface requirement for a licensed operator. However, the Ohio Division of Industrial Compliance has chosen not to enforce the licensing requirement for steam cast iron sectional boilers.

Myth: An Ohio Special boiler cannot be installed outside the state of Ohio.

Fact: An Ohio Special boiler can be installed anywhere in the USA where it meets the local requirements. If you find a deal on a used Ohio Special boiler in Ohio and want to install it in another state, go for it. You just lose the main benefit of the Ohio Special boiler design, as it is built to remain below the heating surface requirement for licensed operator requirements in Ohio only. All the drawbacks of the design still apply, though. It is usually not recommended to install an Ohio Special boiler outside Ohio due to those design trade-offs. But hey, a deal is a deal, right?

Myth: A temporary rental boiler can have over 360 square feet of heating surface since it is a temporary installation.

Fact: No, the 360-square-foot heating surface limit also applies to temporary rental boilers. If a rental boiler is installed at a facility and has over 360 square feet of heating surface, an Ohio-licensed boiler operator is required to be on-site to operate the boiler. Keep this in mind if you are a facility renting a boiler from an out of state boiler rental company. They may not be aware of the Ohio Special rule until they leave you scrambling to find a licensed boiler operator to operate the rental boiler.

Frequently Asked Questions

Q. Does the 360 square feet of heating surface restriction apply to low pressure steam boilers?

A. Yes, a low pressure steam boiler that has more than 360 square feet of heating surface can only be operated by a person who holds either an Ohio stationary engineer, high pressure boiler operator, or low pressure boiler operator license. A person working under the direct supervision of a license holder can also operate the boiler.

(Source: Ohio Revised Code 4104.05(A))

Q. Does the 360 square feet of heating surface restriction apply to high pressure steam boilers?

A. Yes, a high pressure steam boiler that has more than 360 square feet of heating surface can only be operated by a person who holds either an Ohio stationary engineer or high pressure boiler operator license. A person working under the direct supervision of a license holder can also operate the boiler.

(Source: Ohio Revised Code 4104.05(B))

Q. What does the 30 horsepower restriction apply to?

A. The 30 horsepower restriction only applies to stationary steam engines. A stationary steam engine shall not operate at more than 30 horsepower unless the operator has at a minimum an Ohio 3rd Class Stationary Steam Engineer license. A person working under the direct supervision of a license holder can also operate the stationary steam engine. (Source: Ohio Revised Code 4104.05(C))

Q. What if a boiler is 370 square feet of heating surface? Is that close enough?

A. No, a boiler with a heating surface over 360 square feet is required to be operated by a person holding the appropriate Ohio boiler operator license.

Q. Is there a way to operate a boiler over 360 square feet of heating surface and not maintain continuous manned attendance of a licensed boiler operator in Ohio?

A. Yes, in 2015, the Ohio Administrative Code Rule 4101:4-10-01 went into effect to remove the requirement for continuous manned attendance by a licensed boiler operator of a boiler over 360 square feet of heating surface. The code only applies to non-solid-fuel-fired steam boilers, and requirements differ depending on the boiler fuel input rating. If you want to read more about the requirements, we wrote another blog to help you here: Ohio Licensed Operator Exemption Explained.

(Source: Ohio Administrative Code 4101:4-10-01)

Q. Where is the heating surface of a boiler listed?

A. The heating surface of a boiler is required to be listed near the ASME information permanently attached to the pressure vessel. Depending on the boiler design, the information will either be permanently stamped into the pressure vessel or stamped onto a metal plate permanently attached to the vessel.

Q. If a boiler room has several boilers, do their heating surface areas get added together for the 360 square foot rule?

A. No, a licensed operator is not required as long as each boiler’s heating surface is less than 360 square feet. A boiler room can have five Ohio Special boilers installed, each with 359 square feet, and a licensed operator is still not required.

Q. How is the heating surface of a boiler measured?

A. The heating surface is the area inside a boiler where heat is transferred into the water. Only surfaces that actually heat water or steam are counted toward the total heating surface. For more details, refer to ASME BPVC.I-2023, PG-101 Heating Surface Computation for power boilers, and ASME BPVC.IV-2023 HG-403A Heating Surface for heating boilers.

Q, What are the requirements to get a steam engineer, high pressure boiler operator, or low pressure boiler operator license in the state of Ohio?

A. To get a boiler operator or steam engineer license in Ohio, you must be at least 18 years old and have one year of experience operating the type of boiler or steam engine related to the license you want. The state may also accept a mix of education and experience, provided the superintendent approves it. (Source: Ohio Revised Code 4104.19(B)). Those are the minimum requirements, for more detailed information and steps on how to get a license, visit the Ohio Department of Commerce website here: Ohio Boiler Licensing Requirements.

Glossary

CSD-1 Standard: A Standard written by the American Society of Mechanical Engineers (ASME) to enhance public health and safety around boilers. The Standard covers requirements for the assembly, installation, maintenance, and operation of controls and safety devices on automatically operated boilers directly fired with gas, oil, gas–oil, or electricity. (Source: ASME-CSD-1-2024 CG-110)

Boiler: A closed vessel in which water is heated, steam is generated, steam is superheated, or any combination thereof, under pressure or vacuum for use externally to itself by the direct application of heat from the combustion of fuels, or from electricity or nuclear energy. "Boiler" includes fired units for heating or vaporizing liquids other than water where these units are separate from processing systems and are complete within themselves. (Source: Ohio Revised Code 4104.01(C)).

Heating Surface: The surfaces inside a boiler that transfer heat from the fire or hot gas into the water or steam.

High pressure, High Temperature Water Boiler: A water heating boiler operating at pressures exceeding 160 PSIG (11.03 bar) or temperatures exceeding 250°F (121.1°C) (Source: Ohio Revised Code 4104.01(E)).

High Pressure Steam Boiler: A steam boiler with a maximum allowable working pressure (MAWP) greater than 15 PSI (1.03 bar). This can also be called a power boiler.

Low Pressure Boiler: A steam boiler operating at 15 PSIG (1.03 bar) or less, or a hot water boiler operating at 160 PSIG (11.03 bar) or less and/or 250°F or less. (121.1°C). (Source: Ohio Revised Code 4104.01(F)).

Ohio Special Boiler: A steam boiler intentionally designed with a heating surface just less than 360 square feet, keeping it below the operator-licensing threshold for continuous manned attendance defined in Ohio Revised Code (ORC) 4104.05.

Pressure vessel: A container for the containment of pressure, either internal or external. (Source: Ohio Revised Code 4104.01(G)).

Stationary Steam Engine: An engine or turbine in which the mechanical force arising from the elasticity and expansion action of steam or from its property of rapid condensation or from a combination of the two is made available as a motive power. (Source: Ohio Revised Code 4104.01(I)).

The information in this article is up to date as of December 2025. If any changes are made to the Ohio Special requirements, the article will be updated accordingly. If you believe any of the information is incorrect, please email [email protected] with the article name and proposed changes. This article is for educational purposes and does not replace the advice or interpretation of the Ohio Division of Industrial Compliance, the Board of Building Standards, the Authority Having Jurisdiction, or qualified legal counsel. Local inspectors (AHJ) have final authority on interpretation and enforcement at the installation site.