Ohio Boiler Operator Exemption Explained

Dec 18, 2025

What is the Ohio Boiler Operator Exemption?

Ohio Boiler Operator Exemption Definition: An Ohio Administrative Code Rule that allows boiler owners to operate a non-solid-fuel-fired steam boiler with a heating surface of 360 square feet or more when the boiler has an automated electronic control system. The system must meet the requirements of the ASME CSD-1 Standard when the fuel input is less than 12,500,000 BTU/hr and NFPA 85 Code when the fuel input is greater than 12,500,000 BTU/hr.

The Rule can save boiler owners hundreds of thousands of dollars in payroll costs and the hassle of hiring and managing a full-time staff of licensed boiler operators. Before this rule was put in effect, the only way to avoid the requirement for a licensed boiler operator was to use Ohio Special boilers, which are designed with a heating surface just below 360 square feet.

If you want to read more about Ohio Special boiler design requirements, check out this article here: What Is an Ohio Special Boiler? A Complete Guide to Ohio’s 360 sq. ft. Rule

Article Overview

This article explains:

- What the Ohio boiler operator exemption is and when it came into effect.

- Which steam boilers qualify for operation without a licensed boiler operator.

- The specific documentation and requirements for the exemption process.

- The different requirements for boilers under and over 12.5 MMBTU/hr

- How a boiler operator exemption can be revoked if compliance is not maintained.

TL;DR: Requirements to Qualify for the Boiler Operator Exemption

This exemption allows unattended operation and is conditional. Ongoing compliance is required. All required documentation and maintenance records must be retained and available to the inspector.

Boiler Input Rating Less than 12,500,000 BTU/hr

- Boiler must have an automatic electronic control system meeting the requirements of ASME CSD-1.

- Boiler must be non-solid-fuel-fired only.

- Boiler manufacturer and installing contractor must complete an ASME CSD-1 certification report.

- Installing contractor must provide:

- Operating, testing, servicing, and cleaning instructions (IOMs).

- Complete wiring and piping diagrams.

- A written precaution stating annual testing must be performed by a qualified individual.

- Installing contractor must obtain a receipt of delivery for all required documents.

- Submit the certification report and the receipt of delivery to the Ohio Division of Industrial Compliance Superintendent.

- Owner or user must:

- Implement a preventive maintenance program.

- Ensure responsible employees are trained, knowledgeable, and competent.

- Annual inspection and operational testing is to be performed and documented by a qualified individual.

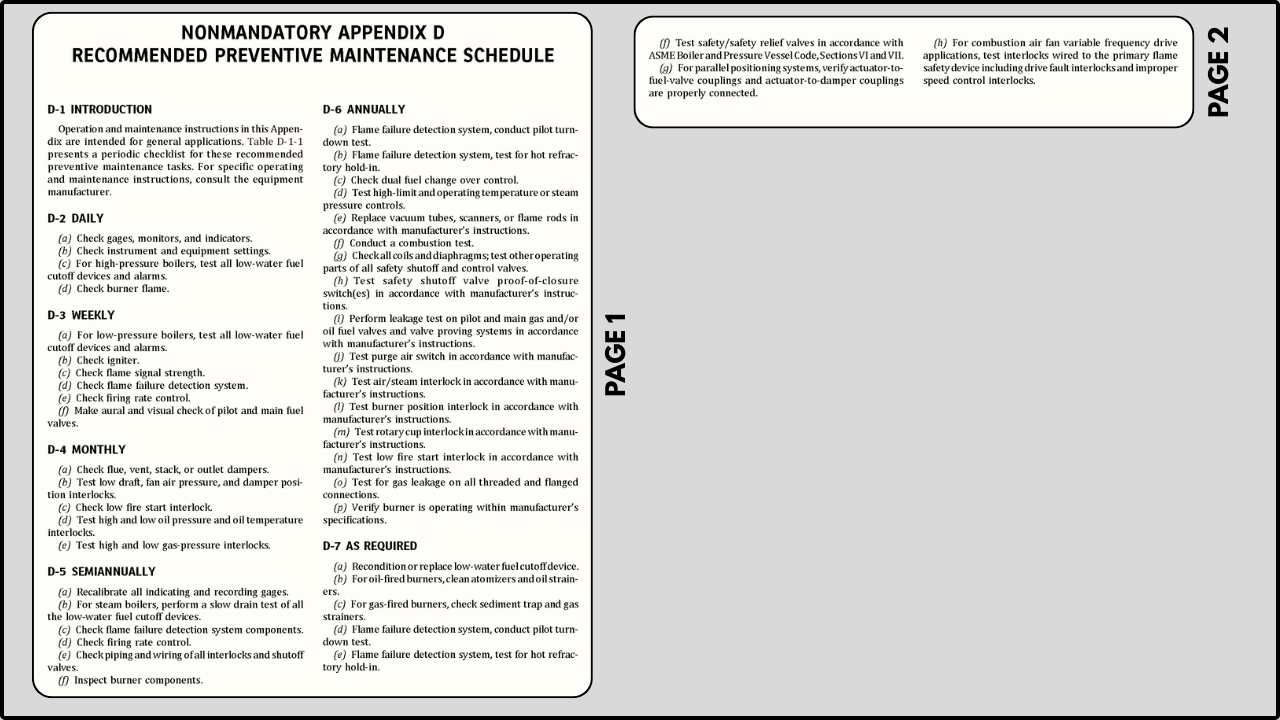

- Daily, weekly, monthly, and semi-annual inspections and operational testing, as outlined by the manufacturer and as recommended in Appendix D of the ASME CSD-1, are to be performed and documented by an employee who has been trained, is knowledgeable, and is competent to operate and maintain such boiler, controls, and safety devices.

Boiler Input Rating 12,500,000 BTU/hr or more

- All of the requirements listed above apply.

- Boiler must meet the requirements of NFPA 85.

- Before installation, the owner must submit a Process Hazard Analysis (PHA):

- Prepared and sealed by an Ohio-licensed professional engineer

- Addressing hazards of unattended operation

- Updated at least every five years

When the Rule Change Happened

Ohio boiler licensing laws have required licensed boiler operators for decades for steam boilers with a heating surface of 360 square feet or more. In 2014, the Ohio Board of Building Standards adopted rule changes allowing a steam boiler with a heating surface greater than 360 square feet to operate without a licensed operator under certain conditions. The rule amendment became effective January 1, 2015.

One of the rule changes was adding the ASME-CSD-1-2021 Standard and the NFPA 85-2021 Code to the list of approved standards in the Ohio Administrative Code (OAC) Rule 4101:4-3-01.

The major rule change was adding provisions that permit a non-solid-fuel-fired steam boiler with an automated electronic control system that conforms to ASME CSD-1 and/or NFPA 85 to be operated without a licensed operator present. This gives boiler owners a chance to have boiler(s) with over 360 square feet of heating surface and not have to staff continuous manned attendance from a licensed operator when the boiler is operating.

This Rule is informally known as the Ohio boiler operator exemption. As long as the boiler owner complies with the requirements in Rule 4101:4-10-01(B) and the conditions are satisfactory to the Chief Boiler Inspector, no licensed operator is required to operate the boiler. The exemption is conditional and may be revoked if the boiler owner fails to maintain compliance with the Rule as determined by a general or special inspector.

But Ohio doesn’t just let owners exempt their boiler and walk away. There are specific requirements the boiler owner must follow to remain in compliance with the code. If you are familiar with ASME CSD-1, the requirements are from the Standard. To ensure boiler owners comply with the requirements, a general or special inspector typically visits the boiler quarterly to check its operation. Not following the requirements can lead to the exemption being revoked and the boiler being shut down until the boiler owner comes into compliance.

Compliance with Rule 4101:4-10-01(B) is overseen by the Chief Boiler Inspector, who is part of the Ohio Division of Industrial Compliance. A general or special inspector will visit the site and ensure the boiler is operated in accordance with the requirements of the Rule.

This can be a substantial cost savings, as a full-time staff of licensed boiler operators can easily cost a company at least $400,000 per year in payroll costs, on top of the hassle of finding and hiring them. This is especially difficult if the boiler plant is farther from a major city, as the population will be smaller and it will be harder to hire people. It is well known that finding licensed operators is difficult due to the low number of new licensees each year and the high number of existing operators retiring.

Requirements for Boilers with Fuel Input Less Than 12.5 MMBTU/hr

The following are the requirements for boilers with a fuel input rating of less than 12,500,000 BTU/hr.

Requirement 1

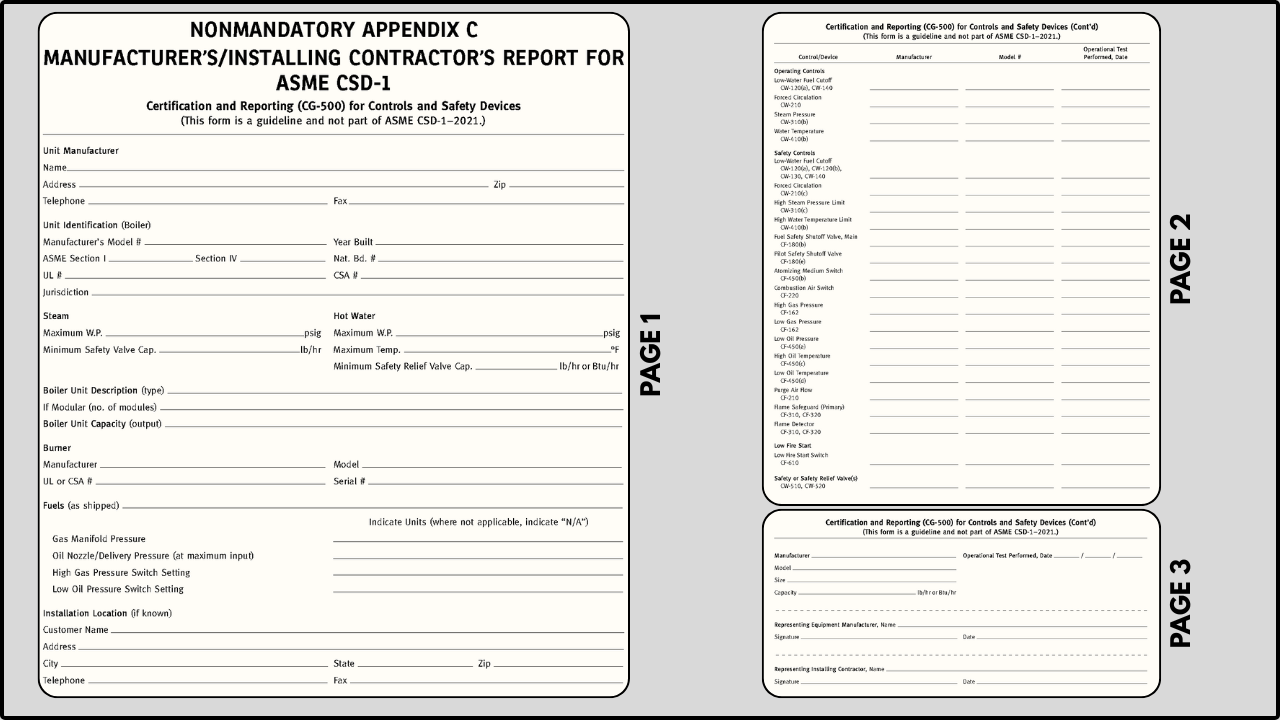

The boiler manufacturer and the installing contractor complete and sign a certification report (similar to the report shown in Appendix C of ASME CSD-1) for each boiler. The certification report is to meet the requirements of Section CG-510 of the ASME CSD-1 and is to identify the manufacturer, model number, and operational test date for each specific boiler control and safety device and certify that each control and safety device was installed and tested in accordance with the manufacturer's installation instructions and the ASME CSD-1. (Source: OAC Rule 4101:4-10-01(B)(4)(a))

For starters, the boiler needs to be built to the ASME CSD-1 Standard. Many boiler manufacturers build all applicable boilers to the Standard at a minimum, but you will want to ensure you specify that the boiler must be built to the Standard.

The ASME CSD-1 Standard includes an appendix at the back that is not part of the Standard but is a helpful reference. Appendix C contains a manufacturer's and installing contractors' report that is an example form. When you order a boiler that complies with the CSD-1 Standard, the manufacturer will include its own completed version of the form for the specific boiler. This is a requirement of CSD-1. Then the company that is the “installing contractor,” which is really the company performing the boiler startup, will complete the form again to confirm that the boiler is in good working order and operating in accordance with the requirements of the CSD-1 Standard. It is very important that the person completing the form takes it seriously and doesn’t “pencil whip” it.

Requirement 2

The installing contractor, who is to be registered in accordance with rule 4101:4-7-01 of the Administrative Code, is to obtain and provide to the owner or user the operating, testing, servicing, and cleaning instructions for the controls and safety devices. Additionally, the installing contractor is to provide to the owner or user the complete wiring and piping diagrams and a written precaution that the annual operating, testing, and servicing of the controls and safety devices is to be performed only by a qualified individual. The contractor is to obtain a receipt from the owner or user for the delivery of these instructions. (Source: OAC Rule 4101:4-10-01(B)(4)(b))

The operating, testing, servicing, and cleaning instructions for the controls and safety devices will be the installation, operation, and maintenance (IOM) documents for the boiler. You need to collect all the specific manuals for each control and safety device installed on the boiler. Sometimes, boiler manufacturers provide all this information; sometimes you have to do it yourself.

You also need to provide the boiler owner with complete wiring and piping diagrams for the boiler. The boiler manufacturer will provide this, and you can just make copies. It is recommended to keep a paper copy of the wiring diagram near the boiler at all times. You can then, if allowed, electronically deliver the wiring and piping diagrams to the boiler owner. If the physical wiring diagram stored near the boiler gets lost, the boiler owner can print a new one.

Once the installing contractor has delivered the IOM and the wiring and piping diagrams, they need to also create a document with a written precaution on it that annual operating, testing, and servicing of the controls and safety devices is to be performed only by a qualified individual. A qualified individual is defined as a boiler service technician who is engaged in and responsible for installation, replacement, repair, or service of the boiler, fuel-burning system controls, and safety devices, and is experienced in such work. This means that the boiler owner and anyone who is appropriately trained and competent to take care of the boiler can do so, but at a minimum, the boiler owner needs to bring in an outside contractor who employs a service technician who meets the definition of a qualified individual to perform the annual maintenance on the boiler.

To complete the requirement, the installing contractor must provide a document to the boiler owner stating that they understand that the annual testing needs to be performed by a qualified individual, and they have received the IOM and the wiring and piping diagrams for the boiler. The document should have a place for the boiler owner to print their name, signature, and date. This is their acknowledgement of the requirements. The installation contractor should keep a copy for themselves and include one with the remaining documents given to the boiler owner as a reminder of the requirements.

Requirement 3

The certification report and the receipt described in paragraphs (B)(4)(a) and (B)(4)(b) of this rule are to be submitted to the superintendent prior to the required inspection and issuance of the certificate of operation prescribed in rule 4101:4-8-01 of the Administrative Code. Failure to submit this documentation may result in the issuance of an adjudication order within the meaning of Chapter 119. of the Revised Code. (Source: OAC Rule 4101:4-10-01(B)(4)(c))

The certification report is the CSD-1 form that the installing contractor completed for the first requirement, and the receipt is the boiler owner's acknowledgement of the information in the second requirement. Those two documents need to be sent to the Ohio Division of Industrial Compliance. You can mail them to the following address or email them to [email protected]

Chief Boiler Inspector

Division of Industrial Compliance

6606 Tussing Rd, Reynoldsburg, OH 43068

For any boiler installation not yet inspected and not assigned an Ohio serial number, the boilers are not to be operated until a certificate of operation has been issued by the superintendent. This is not a hard-and-fast rule, and you can usually get some leniency if the boiler needs to be started and the inspector hasn’t arrived at the site yet. The installing contractor will want to ensure they have copies of all required documents on-site for the inspector to review.

Requirement 4

This requirement is the responsibility of the boiler owner, but the owner rarely knows how to fulfill it without the help of the installing contractor.

The owner or user is to develop, coordinate, and implement a preventative maintenance program and ensure that the employee responsible for maintaining the boiler is trained, knowledgeable, and competent to operate and maintain such boiler, controls, and safety devices. The maintenance program is to be consistent with the manufacturer's recommendations and is to include regular inspections and operational testing for the boiler controls and safety devices. Annual inspection and operational testing is to be performed and documented by a qualified individual as defined in rule 4101:4-1-01 of the Administrative Code. (Source: OAC Rule 4101:4-10-01(B)(4)(d))

The preventive maintenance program will essentially be what the boiler manufacturer recommends in the manual and other documentation. This includes a water treatment and testing program, which is critical for the long life and care of a steam boiler. It is highly recommended that the boiler owner set up a program with a water-treatment company to service the boiler system monthly.

A monthly testing schedule by a water treatment company helps keep problems from getting out of hand too quickly and ensures an adequate chemical supply for the boiler. This is especially important in the first year of operation of the boiler plant after a new installation. Water testing needs to be done more often by trained personnel, but having an outside company able to assist them is well worth the money, especially when it can save on huge repair bills.

When it comes to employee training, the boiler owner needs to decide who will be responsible for the boiler room. These are typically people in the facility's maintenance department. These people need to take a training course satisfactory to the Chief Boiler Inspector on the operation and care of a steam boiler. It is recommended to contact the Chief Boiler Inspector for recommendations on approved training providers.

The annual inspection and operational testing, as mentioned previously, must be performed by a qualified individual. An insurance inspector is still required to come inspect the boiler in addition to the qualified individual. Their inspection process ensures the boiler is operating correctly in accordance with the ASME CSD-1 Standard.

Daily, weekly, monthly, and semi-annual inspections and operational testing, as outlined by the manufacturer and as recommended in Appendix D of the ASME CSD-1, is to be performed and documented by an employee who has been trained, is knowledgeable, and is competent to operate and maintain such boiler, controls, and safety devices. The maintenance records are to identify the manufacturer, model number, set point, the operational tests performed, the operational test date, the inspection results, and who performed the tests or inspection for each specific boiler control and safety device. The maintenance records are to be made available to the inspector for review during the certificate inspection. Failure to provide the required maintenance records may result in the issuance of an adjudication order within the meaning of Chapter 119. of the Revised Code. (Source: OAC Rule 4101:4-10-01(B)(4)(d))

The daily, weekly, monthly, and semi-annual inspections are very important for the boiler owner to maintain. A clear, well-documented program of what responsibilities are required and who is doing what when is important to be successful. If the boiler owner leaves the inspections to whenever the trained person has time or can get to them, they will fall behind and not complete the required paperwork. If the inspector finds that the paperwork is not being completed and that the boiler is being neglected, they can revoke the Ohio special exemption, and the boiler owner will need to hire licensed boiler operators. So it is very important for the health and safety of everyone working in the facility and for the owner's budget that inspections be made part of a clear, defined program, and that leadership ensure they are conducted correctly. When in doubt, it is always best to consult the installing contractor for their recommendation.

Major boiler repairs and downtime are expensive. Hiring a full-time staff of licensed boiler operators is expensive. It is worth it (and legally required) to set up a documented maintenance schedule that aligns with the boiler manufacturer’s requirements and the requirements of Ohio.

Requirements for Boilers with Fuel Input of 12.5 MMBTU/hr and Above

Boilers with a fuel input greater than 12,500,000 BTU/hr have all of the same requirements as boilers with fuel inputs less than 12,500,000 BTU/hr, in addition to one more.

Prior to installation of the boiler(s), the owner is to submit a detailed, written, process hazard analysis (PHA) to the superintendent of industrial compliance that identifies and evaluates the hazards associated with the unattended operation of the boiler and justifies the method(s) proposed to address the hazards. The analysis is to be prepared and sealed by a registered professional engineer holding a certificate issued under section 4733.14 of the Revised Code and is to identify possible incident scenarios, the proposed protection/solution for each scenario, and any such additional information as determined necessary by the superintendent. The PHA is to be reviewed by the owner, updated at least every five years, and submitted to the superintendent for review and filing. Failure to provide the required PHA may result in the issuance of an adjudication order within the meaning of Chapter 119. of the Revised Code. (Source: OAC Rule 4101:4-10-01(B)(5)(b))

The keywords for this requirement are “Before the installation of the boilers”. The boiler owner will need to find an Ohio-licensed professional engineer familiar with boiler systems to prepare a detailed written process hazard analysis. This should be done in a timely manner, not wait until the boiler manufacturer ships the boilers.

Final Thoughts

If you are interested in applying Rule 4101:4-10-01(B) to a boiler installation, you should reach out to the Chief Boiler Inspector before you start purchasing equipment. Early coordination helps avoid purchasing equipment that does not qualify for the exemption or requires costly redesign after the fact.

The licensed operator exemption does not give the boiler owner a free pass once all of the documents are in place. There is continuous ongoing documentation and requirements that must be kept up with other wise the state will remove the exemption from the boiler. Boiler owners need to understand that this exemption process is not a loophole to exploit, but gives them a chance to operate a larger boiler responsibly without a licensed operator.

This exemption process may be right for a facility that doesn't have licensed boiler operators. However, licensed boiler operators still bring valuable knowledge and experience to the boiler room that can help keep the operation running safely and without major repair costs.

Frequently Asked Questions About the Ohio Boiler Operator Exemption

Q. What is the Ohio boiler operator exemption?

A. An Ohio Administrative Code Rule that allows boiler owners to operate a non-solid-fuel-fired steam boiler with a heating surface of 360 square feet or more when the boiler has an automated electronic control system meeting the requirements of the ASME CSD-1 Standard, when the fuel input is less than 12,500,000 BTU/hr and NFPA 85 Code when the fuel input is greater than 12,500,000 BTU/hr.

Q. Does Ohio allow steam boilers over 360 square feet of heating surface to operate without a licensed boiler operator?

A. Yes, provided the boiler qualifies under Rule 4101:4-10-01(B) and complies with the ASME CSD-1 Standard or NFPA 85, depending on the fuel input capacity.

Q. Which boilers qualify for the Ohio boiler operator exemption?

A. Only automatically controlled, non-solid-fuel-fired steam boilers that meet the requirements of the ASME CSD-1 Standard or NFPA 85, depending on the fuel input capacity. Solid fuel boilers using fuel such as coal or wood chips do not qualify.

Q. Can the Ohio boiler operator exemption be revoked?

A. Yes. Failure to maintain compliance with documentation, inspection, testing, or maintenance requirements can result in the exemption being revoked.

Q. Are additional requirements required for boilers over 12.5 MMBTU/hr?

A. Yes. Boilers over 12.5 MMBTU/hr require a process hazard analysis prepared by an Ohio-licensed professional engineer who is familiar with boiler systems.

Q. Can the Ohio boiler operator exemption be applied to rental boilers?

A. While there is no explicit exclusion in the Rule for rental boilers, at this time, the Chief Boiler Inspector has not allowed the Rule to be applied to rental boilers. You can always ask, though.

Glossary

ASME: The "American Society of Mechanical Engineers". Referenced standards, codes, and related technical information developed by this organization can be purchased by logging on to http://www.asme.org. (Source: OAC Rule 4101:4-1-01(B))

Certificate of operation: The certificate issued by the superintendent to the owner or user following the general or special inspector's inspection of a boiler in accordance with section 4104.12 of the Revised Code. (Source: OAC Rule 4101:4-1-01(P))

Contractor: Any person, firm, partnership, company, or corporation that engages in the practice of installing or making major repairs or modifications to any boiler that is subject to the provisions of Chapters 4101:4-1 to 4101:4-10 and 1301:3-5 of the Administrative Code. (Source: OAC Rule 4101:4-1-01(T))

CSD-1 Standard: A Standard written by the American Society of Mechanical Engineers (ASME) to enhance public health and safety around boilers. The Standard covers requirements for the assembly, installation, maintenance, and operation of controls and safety devices on automatically operated boilers directly fired with gas, oil, gas–oil, or electricity. (Source: ASME-CSD-1-2024 CG-110)

Inspector, general: A state of Ohio employee holding a certificate of competency and a valid Ohio commission to inspect boilers and pressure vessels to be used in the state of Ohio. (Source: OAC Rule 4101:4-1-01(W))

Inspector, special: An individual who holds a valid "National Board" commission and a valid Ohio commission to inspect boilers and pressure vessels to be used in the state of Ohio. Special inspectors are typically employed by an insurance company authorized to write boiler and pressure vessel insurance in the state of Ohio but can also be employed as an inspector by the owner-user of the boiler or pressure vessel which is proposed for use or is operating within the state of Ohio. The owner-user is obligated to maintain an established inspection program meeting the requirements of the "National Board" publication "NB-371, Accreditation of Owner-User Inspection Organizations (OUIO)" referenced in rule 4101:4-3-01 of the Administrative Code. In their capacity as a special inspector, they are a representative of the state boiler inspection department, acting independently of their relationship with their employer. (Source: OAC Rule 4101:4-1-01(X))

NFPA: The "National Fire Protection Association." Referenced standards published by this organization can be purchased by logging on to http://www.nfpa.org. (Source: OAC Rule 4101:4-1-01(CC))

Owner or user: Any person, firm, or corporation owning or operating any boiler or pressure vessel. (Source: OAC Rule 4101:4-1-01(GG))

Qualified individual: A service technician trained and thoroughly knowledgeable about the installation, operation, maintenance, and service of the specific boiler fuel-burning system, controls, and safety devices. (Source: OAC Rule 4101:4-1-01(KK))

Superintendent: The superintendent of the division of industrial compliance created in the department of commerce under section 121.04 of the Revised Code, or the person designated by the superintendent as responsible for the enforcement of rules 4101:4-1-01 to 4101:4-10-01 and 1301:3-5-01 to 1301:3-5-10 of the Administrative Code. (Source: OAC Rule 4101:4-1-01(RR))

About the Author

Eric Johnson is the founder of Boilearn, where the mission is to drive continuous learning and improvement in the boiler industry by helping professionals build confidence and grow their careers with practical, real-world skills.

The information in this article is up to date as of December 2025. If any changes are made to the Ohio boiler operator exemption requirements, the article will be updated accordingly. If you believe any of the information is incorrect, please email [email protected] with the article name and proposed changes. This article is for educational purposes and does not replace the advice or interpretation of the Ohio Division of Industrial Compliance, the Board of Building Standards, the Authority Having Jurisdiction, or qualified legal counsel. Local inspectors (AHJ) have final authority on interpretation and enforcement at the installation site.