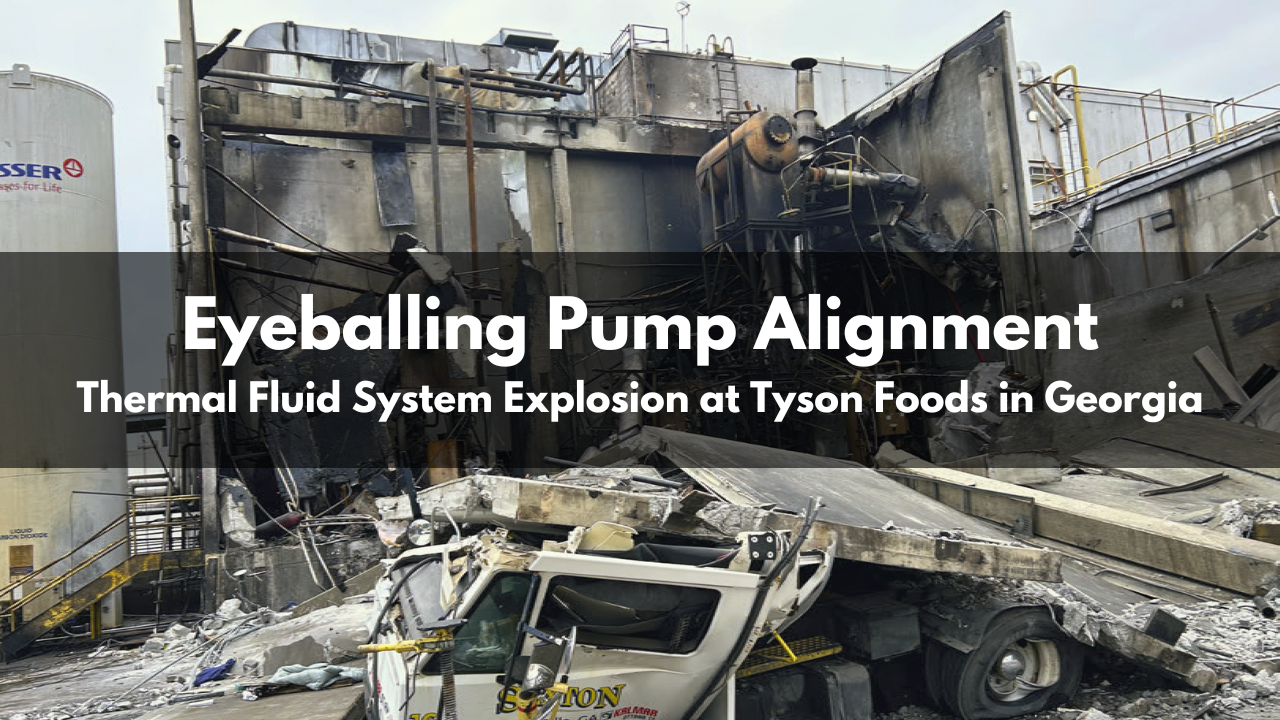

Thermal Fluid System Explosion at Tyson Foods in Georgia

Jan 27, 2026

Two separate views of the fire in the boiler room reaching above the roof on December 26, 2024 the night the accident happened.

On December 26, 2024, an explosion and fire occurred at the Keystone Foods facility, publicly known as Tyson Foods, in Camilla, Georgia, resulting in two people being burned and one fatality. Early reports described the incident as a boiler explosion, but the event was later determined to be caused by a leak from a thermal fluid heating system.

The following is from the OSHA narrative report on the events leading up to and the cause of the accident. A narrative report is OSHA’s understanding of what happened. Minor editing and section headers have been added for clarity and readability.

Thermal Fluid System Overview

The facility consisted of two main production areas, Evisceration and Further Processing. The Further Processing area was used to batter, fry, and package chicken for retail sale. The fryers in the area were heated by three thermal fluid heater systems also called boilers, located in a boiler room sited on the east side of the facility. Two boilers were installed in 1997, and a third was installed in 2018. The boilers heated a heat transfer fluid (Chemical Name: Mineral Oil; Product Name: Paratherm NF) to a temperature of approximately 500F, at a pressure of 40 - 50 PSI, and were fed via pipes to the fryers within the production area. The boilers typically stayed in operation from Monday through Friday. On weekends and extended holidays, the boiler temperature was reduced to approximately 300F in order to save energy costs. The boilers were not turned off completely so that the piping would stay warm and would not have to be brought all the way back up to 500F. Typically, the only time the temperature was brought down below 300F was when a maintenance activity required it. Six 100-pound portable carbon dioxide bottles (2 per boiler) were maintained and inspected in the boiler room for fire suppression purposes.

Timeline of Events

On Thursday, December 26, 2024, the Refrigeration Supervisor was called in while off duty because the boilers were off, and the refrigeration maintenance staff on duty could not figure out how to get them started again. The boiler temperature had been reduced to 300F for the Christmas holiday, and the maintenance staff was attempting to return it to full operation; however, due to an unknown malfunction, the boiler temperature had dropped to approximately 100F. The Refrigeration Supervisor found that a weld had broken on a bracket associated with pump #1, causing the system to shut down. Pump #1 was one of the pumps that fed the heat transfer fluid through the system.

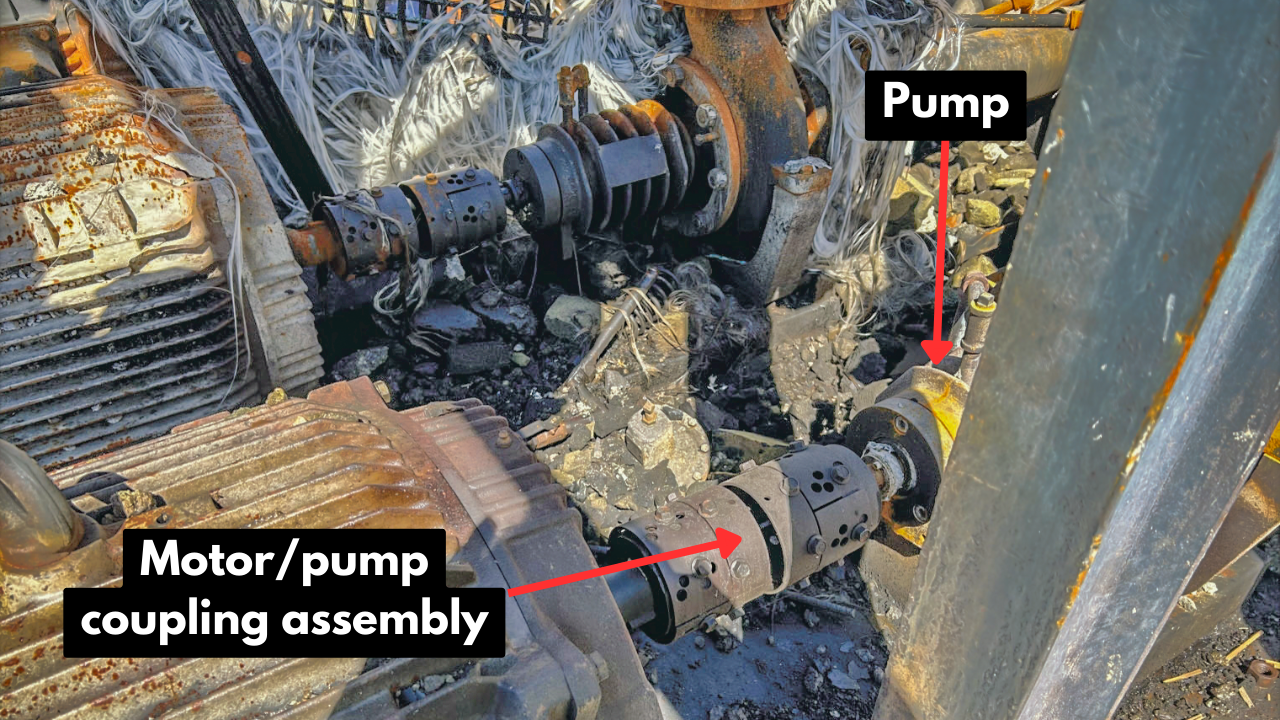

The Refrigeration Supervisor stated that he put the bracket back in place, welded it, put a new coupling on it, and started it back up. The Refrigeration Supervisor also stated that they performed an alignment during the coupling installation. The boiler temperature was raised in increments from approximately 100F to approximately 540F over the course of about one hour. The Refrigeration Supervisor then called the Production Manager and asked them to start one fryer to put a load on the system. They then observed the system to see how it responded. The system appeared to be functioning properly; therefore, the Refrigeration Supervisor contacted the Production Manager and asked them to put another fryer online. The Refrigeration Supervisor stated that they decided to take a break since they had been working for 4.5 to 5 hours and left the boiler room. Approximately 10 minutes later, they were informed that there was a fire in the facility. Witnesses reported observing an initial blast releasing the heat transfer fluid and spraying one of the Refrigeration Technicians. The boiler room was then seen filling with a white mist, followed by a second explosion that resulted in the boiler room wall collapsing and fire.

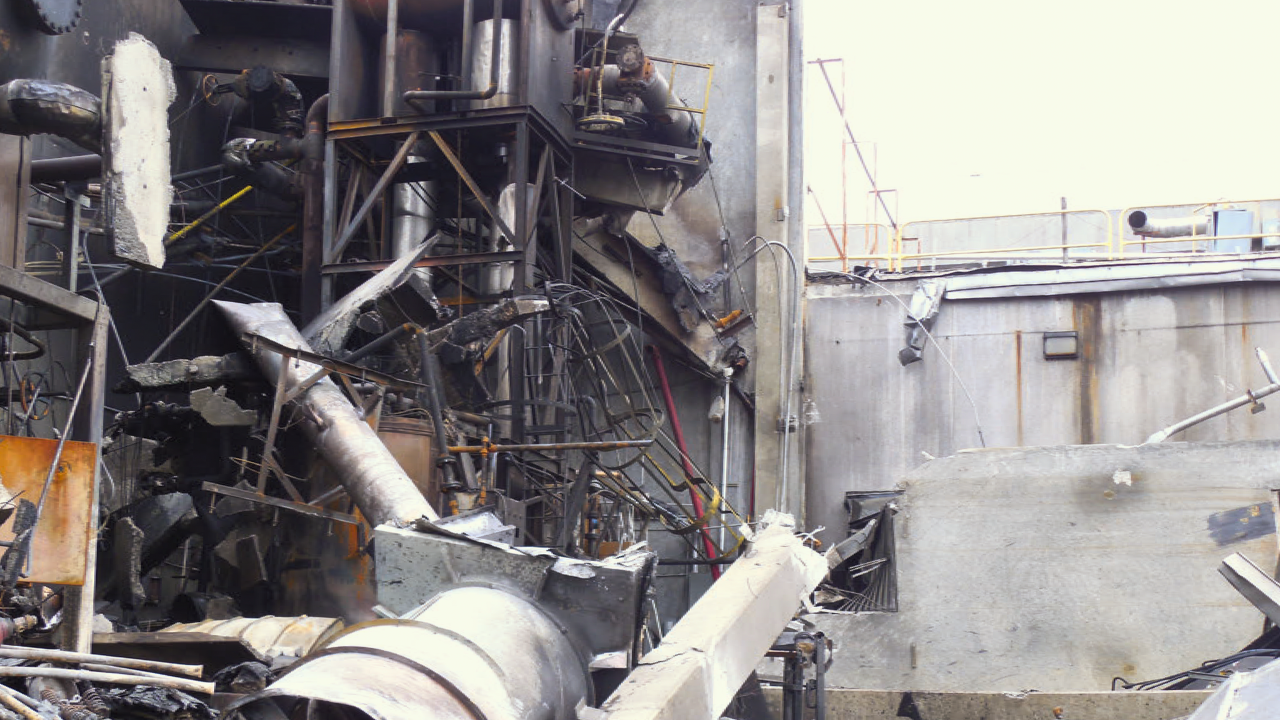

Aftermath of the explosion and fire at the Tyson Foods facility in Camilla, GA.

Details Identified During Interviews

When the Refrigeration Supervisor arrived on site, they were assisted by two first shift Refrigeration Technicians. The shift changed at 6:00 pm, and the Refrigeration Supervisor was joined by two second shift Refrigeration Technicians. The Refrigeration Supervisor and Technicians stated that the Technicians worked under the direction of the Supervisor. In addition, each stated that the Supervisor performed the work, and the Technicians watched and gathered tools or parts as needed.

The Refrigeration Supervisor stated that after they installed the new coupling on pump #1, they aligned it using a micrometer. Interviews indicated that the pump was not aligned using any tools and was "eyeballed". Employer training states that the shaft/coupling will be aligned using either a straight edge and a feeler gauge or a dial Indicator. Witnesses indicated that neither of these methods was used on December 26, 2024. In addition, the employer training and equipment training/manual states that both a cold alignment and a hot alignment should be performed following a coupling installation.

It was stated that a coupling was changed out on pump #2 (adjacent to pump 1) "a few months ago". A document provided by the employer shows that couplings were requested from the parts department three times in 2024: February 16, December 9, and December 26. The Technician who had changed out the coupling on pump #2 on December 9th stated that they do not do alignments when they change the coupling; a third party would come out and do that. They stated that they had assisted the Refrigeration Supervisor in changing couplings, but had never seen them perform an alignment or perform one themselves.

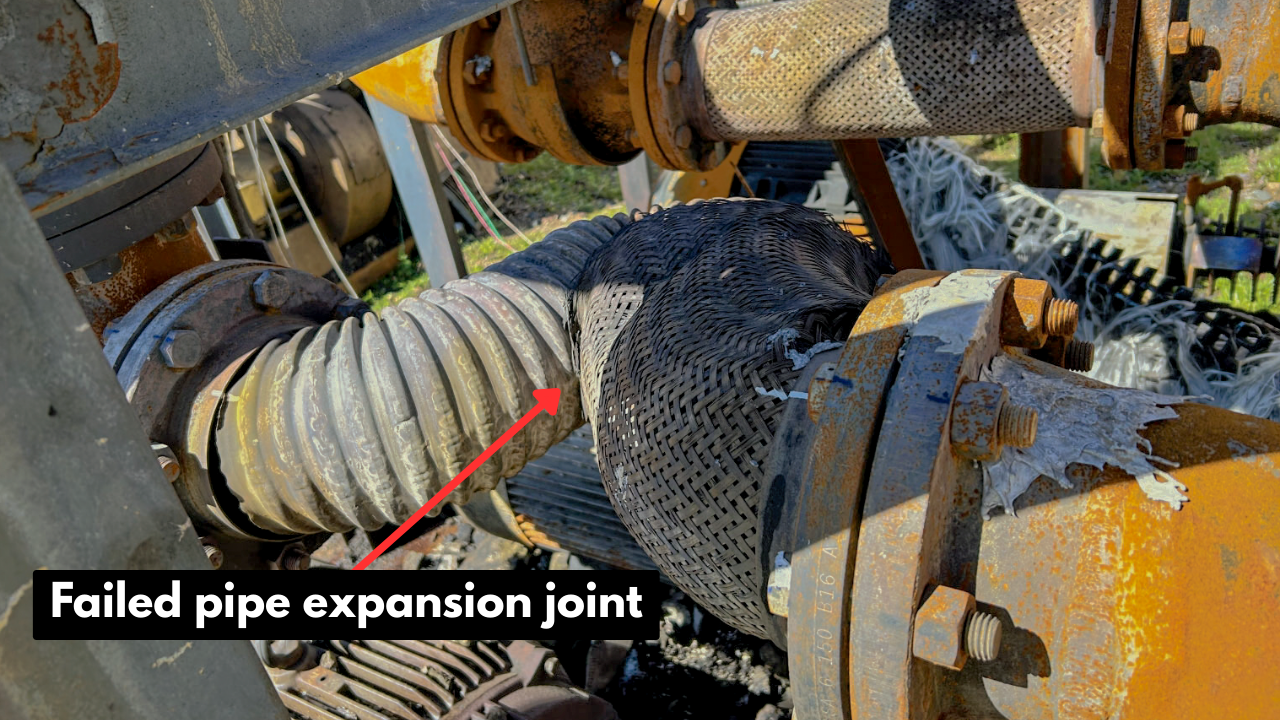

Refrigeration maintenance staff performed checks on the boiler system every two hours, where they checked temperatures and pressures and looked for anything "out of the ordinary". This typically included looking for leaks and listening for any unusual sounds. The staff also performed more detailed inspections every two weeks as part of their preventive maintenance (PM) program. After reviewing the daily and weekly PM information and discussing the inspections in interviews, it was determined that they did not specifically pay attention to the flex joints in the system. The employer provided a Fulton training document used to train the staff that stated, "closely inspect all flex joints".

Aftermath of the explosion and fire at the Tyson Foods facility in Camilla, GA.

Findings Regarding the Cause of the Incident

The Compliance Safety and Health Officer (CSHO) obtained information from the Georgia State Fire Marshal's Office - Arson Unit, local first responders, and consulted with the OSHA Hazard Response Team (HRT). Based on this information, on-site inspection, and interviews, it was determined that a flexible hose carrying the heat transfer fluid located above pump #1 ruptured. According to the Refrigeration Supervisor, the flexible hose was original to the system and therefore 25 to 30 years old. Pump #1 had not been aligned per manufacturer recommendations (cold and hot alignments) prior to being returned to full operation, likely causing excess vibration. The bracket for pump #1 broke on December 26, 2024, causing the pump to shut down, possibly due to excessive vibration. Pump vibration issues and the age of the flexible hose may have contributed to the hose failing and the subsequent explosion.

This concludes the OSHA narrative report.

Aftermath of the explosion and fire at the Tyson Foods facility in Camilla, GA.

Aftermath of the explosion and fire at the Tyson Foods facility in Camilla, GA.

The red semi truck sleeper was crushed by the falling wall of the boiler room.

Observations and Lessons Learned

Excessive Vibration Should Never Be Ignored

Vibration, even when it seems minor, will tear equipment apart and can quickly get worse. Excessive vibration from an improperly aligned pump and motor can quickly damage bearings, seals, and cause fasteners to come loose. In this case, the pump base cracked due to vibration, damaging the coupling and causing the pump to stop and the system to shut down. Those were indicators that a larger issue needed to be addressed beyond a replacement part. It is unknown if the flexible pipe on the pump discharge was damaged before the base was welded and the pump coupling replaced, which shortly led to the leak and explosion.

Failed pipe expansion joint on discharge of the pump.

Pump and Motor Alignment Must Be Done Properly

While pump and motor alignment can be done with manual tools such as a straight edge, dial indicator, feeler gauges, and calipers, a laser alignment system is worth the investment. A good laser alignment system will indicate the shaft misalignment and suggest how to correct it. It reduces trial-and-error when aligning with manual tools. However, ongoing training is needed to keep users up to date on how to use the tool. Companies cannot expect someone to use a laser alignment tool once every 6 months and remain proficient.

Laser alignment also allows an electronic report to be generated that proves the alignment was performed properly and within tolerances, rather than relying on someone to say or manually document it.

Motor and pump coupling assembly. Parts of the failed pipe expansion joint can be seen in the background.

Cold and Hot Alignment Are Needed for Thermal Fluid Pumps

The training documents provided by the thermal fluid heater manufacturer say that cold and hot pump alignment is critical for the pump to operate properly. Cold alignment should be done to get the pump close enough that it can run without excessive vibration and allow the system to heat up. When the pump and piping heat up, the pump will move slightly, altering the shaft's alignment. Since the pump will operate most of the time when the system is hot, the alignment needs to be rechecked at the operating temperature. This ensures the pump and motor are aligned correctly within the tolerances for normal operating conditions.

Training is Continuous, Not a One-Time Event

It was determined that personnel at the facility had received training on properly aligning the pump and motor, as documented in the company's internal records. However, documents are just pieces of paper with writing on them and do not ensure that personnel are performing tasks properly. Training is a continuous process of tips, reminders, and guidance on using internal documents for repair processes. A one-time training event does not guarantee that the task will be completed properly from that point forward if there is no system to ensure it is completed in accordance with the training procedures.

Providing documentation at the equipment, rather than an internal file management system or a faraway manager's office, can help personnel reference it when performing tasks, rather than having to source it from a cumbersome file management system. In a production environment, there are so many pieces of equipment that personnel may not even know that documentation exists for a task.

Regular System Inspections are Necessary

A thermal fluid system should be regularly inspected and should have a structured system for documenting inspections. Just telling someone to inspect the system won't yield repeatable results. The personnel inspecting the system do not need to be experts on it, but should be able to identify when conditions change from normal. A good structured inspection process would clearly define what is not normal and the appropriate actions to take. In addition to regular in-house inspections, it would be helpful to bring in an outside expert at least every 6 months to review the system and check the logs from previous inspections for any recurring issues. A structured inspection process is not a foolproof way to prevent an accident, but when done right, it should catch issues that develop slowly, such as bearing noise, excessive vibrations, rising heater stack temperature, damaged piping, and small leaks that will get worse.

Summary and Final Observations

This unfortunate event shows how quickly a thermal fluid system can become dangerous once normal operating conditions change and hot oil is released from the system. Although it was initially reported as a boiler explosion, this was a loss-of-containment event involving a high-temperature thermal fluid system operating well above the fluid’s 300°F flash point. The conditions that led up to the incident did not happen all at once. They developed over time through pump vibration, alignment issues, and aging components. Thermal fluid systems are widely used in process facilities because they allow high temperatures to be maintained at lower pressures than comparable steam systems, yet the energy stored in a hot oil system is often underestimated. When early warning signs are treated as isolated maintenance issues instead of indicators of a larger problem, the risk increases. Understanding how these systems behave during startup, shutdown, and upset conditions is critical to reducing the likelihood of similar incidents.

This article used the OSHA investigation report as the main source of information. This article is meant for learning and training purposes for readers to help improve safety practices and is not intended to place blame on any party involved in the event.

About the Author

Eric Johnson is the founder of Boilearn, where the mission is to drive continuous learning and improvement in the boiler industry by helping professionals build confidence and grow their careers with practical, real-world skills.